Comparing Conventional Warehouse Digitalization with Automated Warehouse (AS/RS) Investment

In the era of Industry 4.0, the transformation of warehouses has become imperative for businesses looking to streamline operations, enhance efficiency, and meet the demands of the ever-evolving market. Two prominent approaches to achieve this are conventional warehouse digitalization and investments in Automated Storage and Retrieval Systems (AS/RS). CT-TECHNOLOGIES will explore and compare these two strategies, highlighting their advantages and drawbacks to help businesses make informed decisions about warehouse management.

A. Conventional Warehouse Digitalization

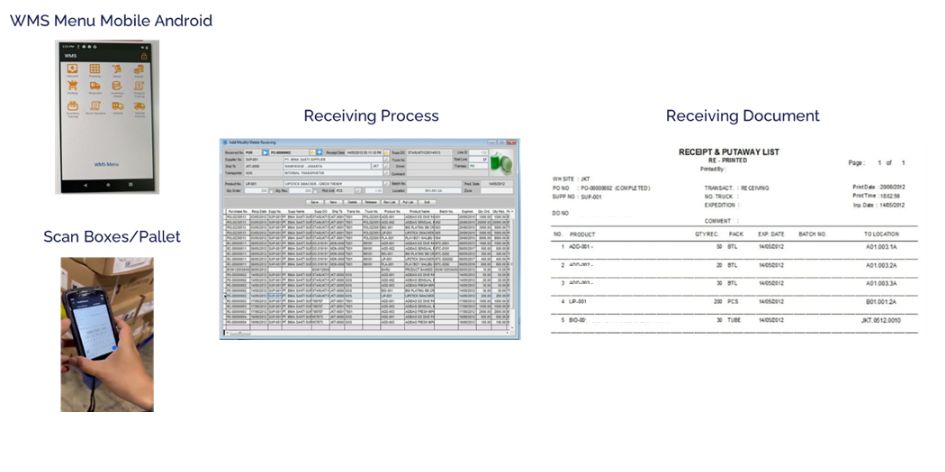

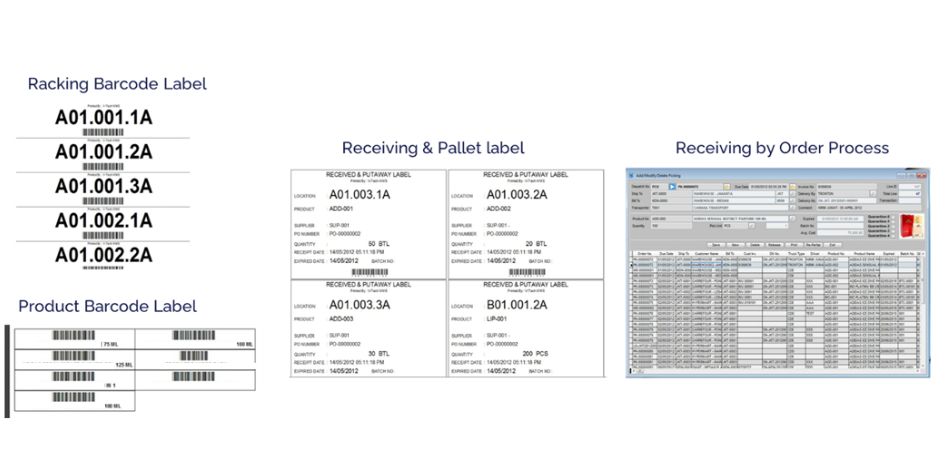

Conventional warehouse digitalization involves adopting digital technologies and software solutions to optimize warehouse operations. It typically includes the implementation of Warehouse Management Systems (WMS), barcode scanners, RFID systems, and other tools to enhance inventory tracking, order processing, and overall operational visibility.

Advantages of Conventional Warehouse Digitalization

- Cost-Effective Entry Point: Conventional digitalization is often a more cost-effective starting point for small to medium-sized businesses looking to improve their warehouse operations.

- Flexibility: This approach allows for the gradual integration of digital technologies, making it easier for businesses to adapt to changes.

- Scalability: Businesses can scale their digitalization efforts as they grow, avoiding large upfront investments.

- Improved Visibility: WMS and tracking technologies provide better visibility into inventory, enabling more accurate demand forecasting and inventory management.

Drawbacks of Conventional Warehouse Digitalization

- Limited Automation: This approach relies on manual labour for most tasks, limiting the degree of automation achievable.

- Efficiency Gains Are Limited: While digitalization can enhance certain aspects of warehouse operations, it may not lead to significant efficiency gains compared to AS/RS.

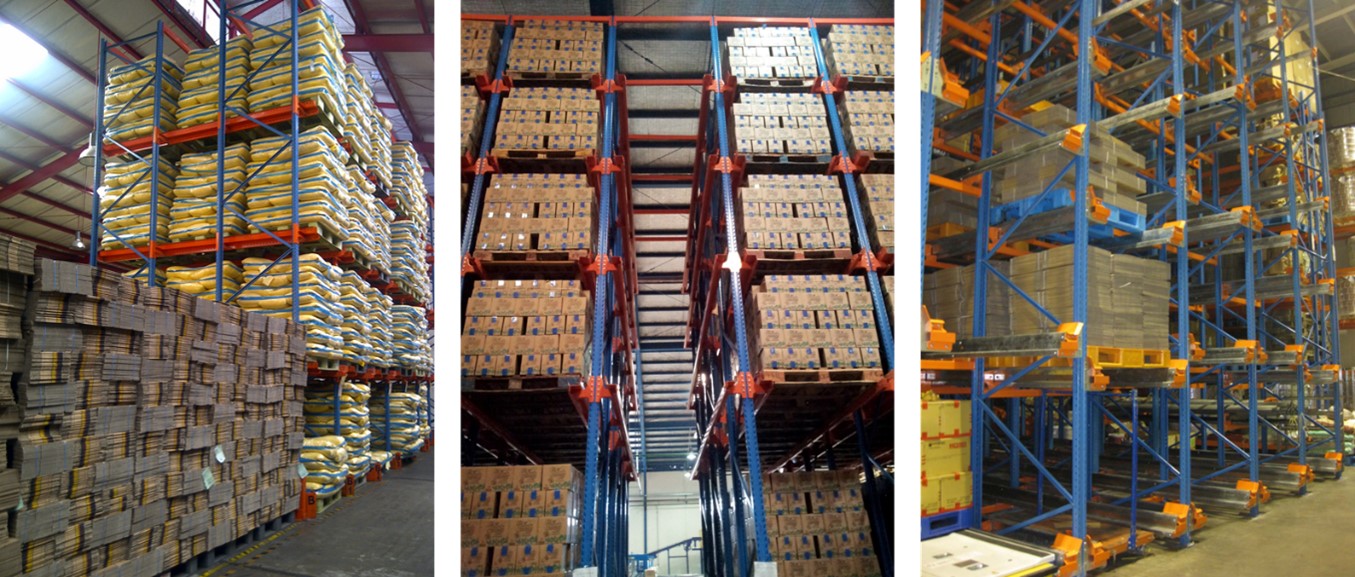

Conventional Rack Storage Systems

a. Selective Pallet Racking and Mobile Pallet Rack

Advantage: High (100%) Selectivity, Area Utilization: 40% Storage, 60% Gangway.

High Stock Keeping Unit (SKU), Suitable for Distribution Center ( DC ) Warehouse, Raw Material (RM) Warehouse.

b. Double Deep Pallet Rack

Advantage: Density is better than Selective Pallet Racking (SPR), Area Utilization: 60% Storage, 40% Gangway.

Mid SKU, Suitable for DC Warehouse, third-party logistics (3PL).

c. DRIVE-IN & Shuttle Rack

Advantage: High Density, Area Utilization: 70% Storage, 30% Gangway.

Low SKU, Suitable for Factory Warehouse (Raw Material & Finished Goods).

d. Multi-Tier Longspan Shelving

Boxes/Pcs Picking

High SKU, Suitable for Retail DC Warehouse, Archive Warehouse Storage Services, Small Spare Parts

Conventional Warehouse Optimization Through Digitalization Warehouse Management System

B. Automated Warehouse (AS/RS) Investment

Automated Warehouses, equipped with Automated Storage and Retrieval Systems (AS/RS), are the epitome of warehouse automation. AS/RS systems is a mechanical system that automates the process of storing and retrieving goods from storage shelves using devices such as Stacker Cranes, Conveyors and Control Devices (WMS, WCS & PLC). AS/RS helps increase efficiency, accuracy and speed in managing inventory and the picking process.

Advantages of Automated Warehouse (AS/RS) Investment

- High Efficiency: AS/RS systems significantly reduce labour requirements and enable 24/7 operation, resulting in higher efficiency and productivity.

- Accuracy and Precision: Automation reduces human error, leading to more accurate inventory management and order fulfilment.

- Space Optimization: AS/RS systems are designed to maximize vertical space utilization, reducing the need for extensive warehouse footprints.

- Scalability: Automated warehouses can be easily scaled to accommodate increased demand without proportionately increasing labour costs.

Drawbacks of Automated Warehouse (AS/RS) Investment

- High Initial Investment: Implementing AS/RS systems involves substantial upfront costs, which can be a barrier for smaller businesses.

- Complexity: Maintaining and troubleshooting complex AS/RS systems requires specialized skills and knowledge.

- Limited Flexibility: Once an AS/RS system is in place, making changes or adaptations can be challenging and costly

Automatic Storage and Retrieval System

a. Freestanding ASRS Cold Storage

b. Rack Supported Building (Rack Clad) ASRS

c. Rack Supported Building (Rack Clad) ASRS Cold Storage

C. Choosing the Right Approach

The choice between conventional warehouse digitalization and AS/RS investment depends on various factors, including a company's size, budget, and long-term goals.

For small and medium-sized enterprises (SMEs) with limited budgets and gradual growth plans, conventional warehouse digitalization may be the more practical choice. It allows for incremental improvements without the need for massive capital investments.

In contrast, large enterprises with high order volumes and a strong need for efficiency and accuracy may find AS/RS investment more appealing. The initial cost is offset by long-term savings through reduced labour and operational expenses.

Due to the significant efficiency in energy and labour costs, the Annual Cost for ASRS is lower compared to Conventional Warehouse Digitalization, but the initial investment value for ASRS is relatively very high.

An ROI (Return On Investment) evaluation is needed, namely how long it will take to get back the initial investment in ASRS through operational cost savings (reduction in labour) and efficiency (savings in energy use). The faster we can achieve ROI, the more profitable this ASRS investment will be.

In conclusion, both conventional warehouse digitalization and AS/RS investment have their merits and drawbacks. Businesses should carefully evaluate their specific needs, budget constraints, and growth expectations when deciding which strategy to pursue. Ultimately, the right choice can lead to improved warehouse operations and a competitive edge in the evolving marketplace.

We’d appreciate the opportunity to help you further, whether that be more information or a quote. Our team is with you each step of the way to ensure that your project is seamless and expertly executed.

Call CT-TECHNOLOGIES today to speak with our professional experts.